Automated Seeding Trays, Misting Systems, and Climate Control Tips for Large-Scale Seedling Nurseries

Running a large-scale seedling nursery demands efficiency and precision, especially when producing thousands of seedlings for crops like vegetables, flowers, or trees. Automating key processes—like seeding, watering, and climate management—can save time, reduce labor costs, and ensure consistent results. In this guide, we’ll dive into automated seeding trays, misting systems, and climate control tips tailored for a high-output nursery setup. Let’s optimize your operation for success!

Why Automate Your Seedling Nursery?

Automation revolutionizes mass production of seedlings by reducing manual labor and enhancing consistency. Automated seeding trays simplify planting, misting systems provide optimal moisture levels, and climate control maintains conditions optimized across huge areas. Combined, they increase germination rates, enhance seedling health, and enable you to upscale without compromising on quality.

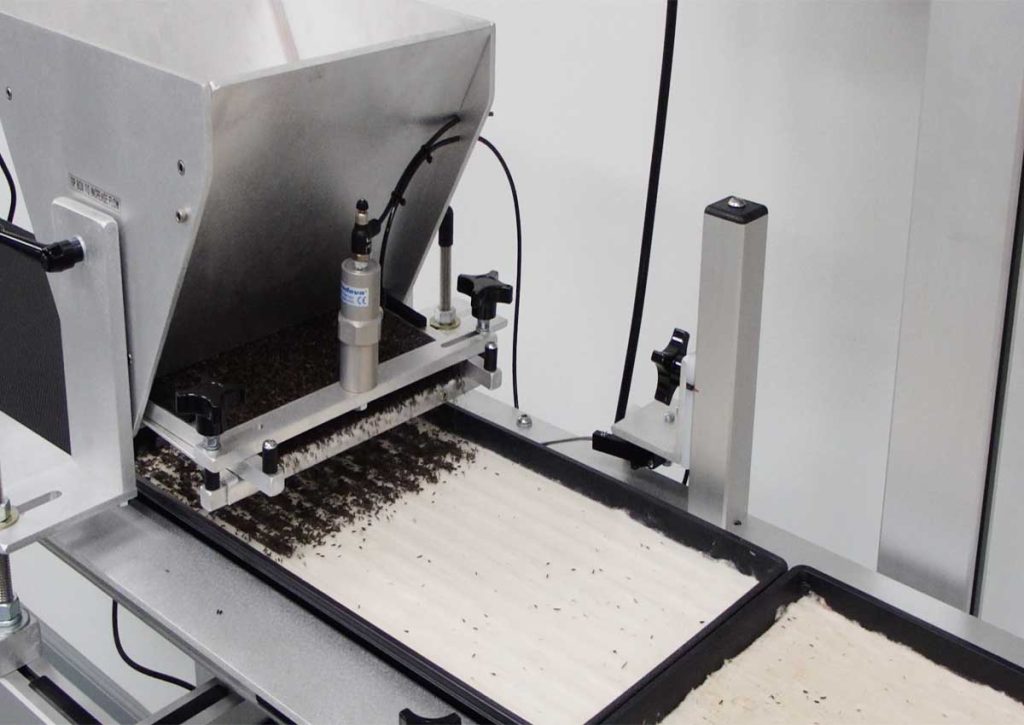

Automated Seeding Trays: Setup and Benefits

Automated seeding trays change the way you sow seeds in a large-scale nursery. Here’s what you need to know:

1. Types of Automated Seeding Trays

- Drum Seeders: Employ rotating drums to release seeds into trays—ideal for medium to large seeds (e.g., cucumbers, tomatoes). Output: 200-600 trays/hour.

- Vacuum Seeders: Suction systems scoop and place small seeds (e.g., lettuce, flowers) with accuracy. Output: 400-1,000 trays/hour.

- Needle Seeders: Ideal for irregular seeds (e.g., bitter gourd), using needles to pick up and plant. Output: 150-400 trays/hour.

Drum Seeders

Vacuum Seeders

Needle Seeders

- Key Features

- Adjustable seed spacing and depth for various crops.

- Standard tray compatibility (e.g., 128- or 200-cell).

- Conveyor integration to transport trays after seeding.

- Setup Tips

- Use with a tray filler (e.g., 300 trays/hour capacity) to pre-fill soil evenly.

- Calibrate the machine for every seed type—test runs avoid over- or under-seeding.

- Place close to a power source (220V or three-phase) and have a compressor on hand for vacuum models.

- Advantages

- Saves 80% of seeding time versus hand-planting.

- Minimizes seed waste with accurate placement.

- Guarantees even germination—essential for large quantities.

Tip: Purchase a mid-range model (e.g., $5,000-$15,000) to begin with, then upgrade as production increases.

Misting Systems: Hydrating Seedlings

A misting system provides uniform moisture—a seedling’s requirement for success on a large scale. Here’s how to install it:

1.System Types

- Overhead Misting: High-pressure nozzles (0.2-0.5 mm) mist over trays. Covers 500-1,000 sq ft per unit.

- Fogging Systems: Ultra-fine droplets (10-20 microns) for high-humidity crops like bitter gourd or orchids.

- Bench Misting: Targeted nozzles under benches treat specific areas—perfect for mixed crops.

Overhead Misting

Fogging Systems

- Components

- High-pressure pump (e.g., 800-1,000 PSI) for uniform mist distribution.

- Stainless steel or PVC piping with clog-proof nozzles.

- Moisture sensor or timer to automate cycles (e.g., every 15 minutes, 10 seconds).

- Installation Tips

- Position nozzles 2-3 ft above trays for complete coverage—2-4 ft apart depending on tunnel size.

- Filter water to avoid clogging; install a 50-micron filter in the system.*

- Test spray patterns to prevent over-wetting edges or under-watering centers.

4.Benefits

- Maintains 70-90% humidity—ideal for germination.

- Saves labor versus manual watering.

- Avoids seedling stress due to variable moisture.

Pro Tip: Use in conjunction with a drainage system (e.g., guttered benches or sloped floors) to control excess runoff in large tunnels.

Climate Control Tips for Large Nurseries

Temperature, humidity, and light control across a large nursery ensure seedlings grow. Here are useful tips:

1. Temperature Management

- Heating: Install gas-fired heaters (e.g., 250,000 BTU) or radiant heat tubes for winter—70-80°F (21-27°C) day/65-70°F (18-21°C) night.

- Cooling: Apply evaporative cooling pads (6-8 inch) with exhaust fans (48-inch diameter) to reduce summer temperatures by 10-20°F.

- Thermostats: Install multiple digital units (e.g., one for every 1,000 sq ft) with a central controller for zone control adjustments.

2. Humidity Control

- Combine misting systems with dehumidifiers (e.g., 100-pint capacity) in humid climates to prevent fungus growth.

- Apply hygrometers to measure levels—set 50-80% based on crop stage.

- Ventilate with roll-up sidewalls or fans (10,000-20,000 CFM) to balance humidity after misting.

3. Lighting Optimization

- Mount high-output LED grow lights (800-1,200 µmol/m²/s) on adjustable racks—cover 50-100 sq ft per fixture.

- Operate lights 12-16 hours/day for vegetative growth; use timers for consistency.

- Reflectors or white tunnel liners increase light efficiency in large areas

4. Automation Integration

- Hook up heaters, fans, and lights to a climate controller (e.g., Argus or Priva systems) for real-time adjustments.

- Install CO2 generators (1,000-1,500 ppm) to accelerate growth in sealed tunnels—track with sensors.

- Utilize blackout curtains for photoperiod-sensitive plants such as poinsettias.

Pro Tip: Purchase a backup generator (e.g., 20-50 kW) to maintain climate systems during power outages—essential for high-volume reliability.

Integrating Automation for Max Efficiency

Workflow: Seed trays using an automated seeder, transport them under misting zones, and let climate controls do the rest.

Monitoring: Monitor seeding rates, misting schedules, and climate remotely using a nursery management app (e.g., Growlink).

Maintenance: Regularly clean seeder heads, misting nozzles, and sensors to avoid downtime.

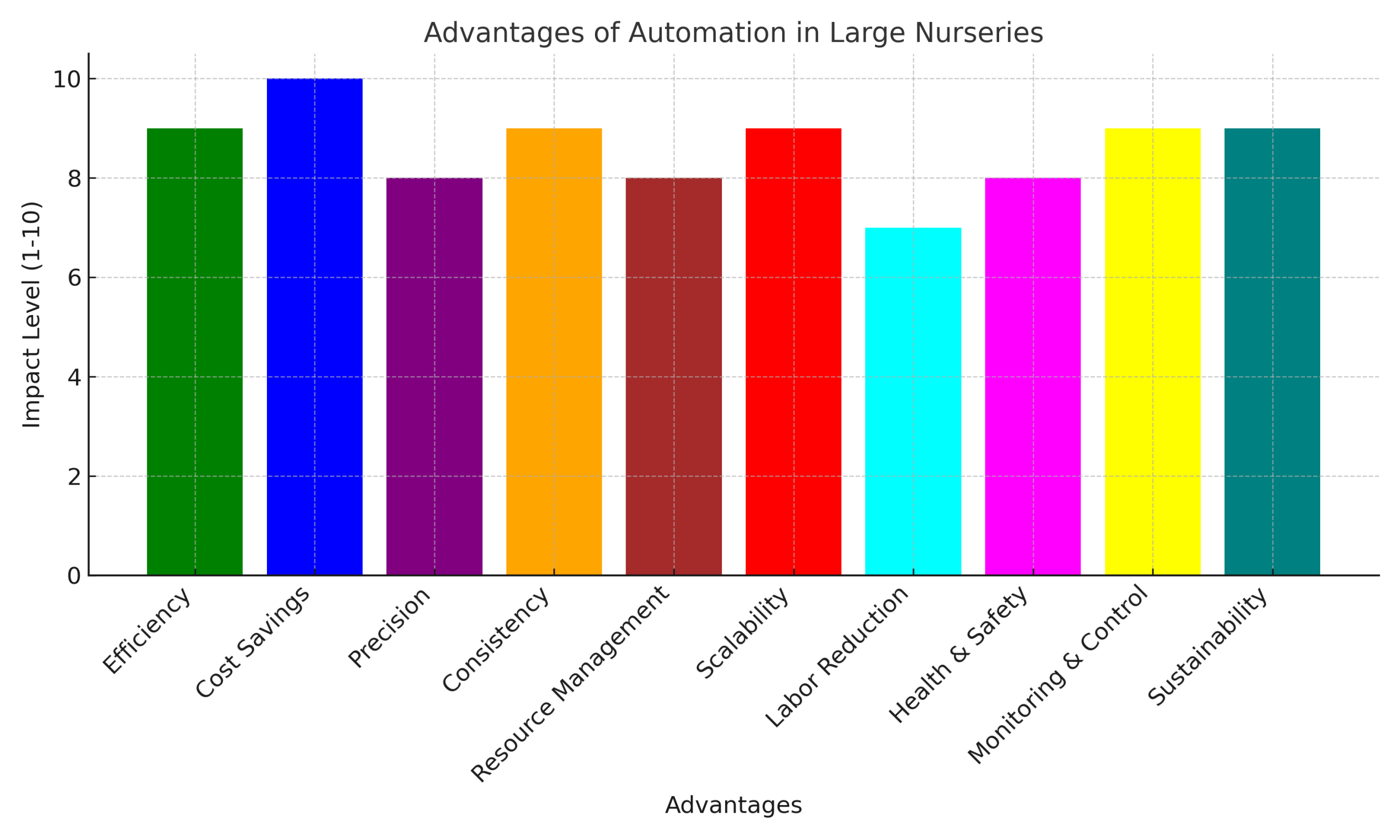

Advantages of Automation in Large Nurseries

Scalability: Manage 50,000+ seedlings with few staff members.

Consistency: Consistent seeding, watering, and climate minimize variability.

Profit Boost: Reduced labor cost and increased output fuel revenue.

Conclusion

Automated seeding trays, misting systems, and smart climate control are the backbone of a high-performing, large-scale seedling nursery. By integrating these technologies, you’ll streamline operations, optimize seedling health, and set the stage for massive production runs. Ready to automate? Equip your nursery with these tools and tips, and watch your efficiency soar!

Add comment